This website use cookies to ensure you get the best experience on our website.

PREOWNED

LINEA BARRETTE

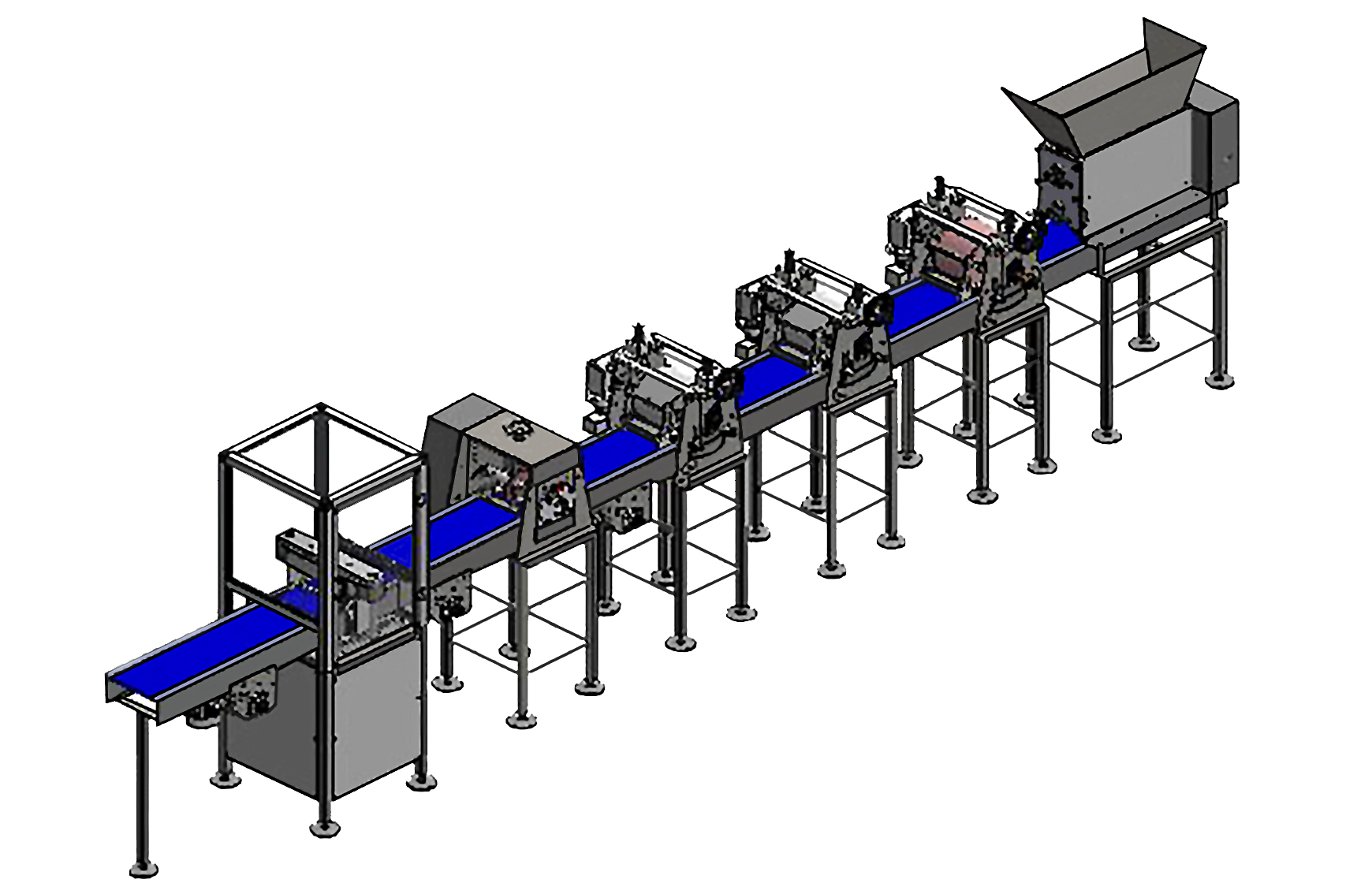

SNACK-BAR MANUFACTURING LINE

Snack-bar manufacturing line, the bars are made starting from a dough based on extruded cerals, dried fruits and legumes, spices etc.

The whole line is composed by these elements:

- Product loading system with “troller”

-

Product loading at the exit of the oven in order to carry the product on the hopper of the bar line

- Made of AISI 304

- Loading level control

- Fixed structure

-

Product loading at the exit of the oven in order to carry the product on the hopper of the bar line

- Nr. 8 60 liters troller for product loading

- Entirely made of AISI 304

- Snack-bar machine

- Multifunction machine that produces different sizes of snackbars, made of dried cereals or, by means of HMI panel recipe selections, you can easily start the production of bars extruded from different types of dough such as date, apricot, figs, etc For both of the cases, the last operation is the trasversal cut. The actual dimension of the bar can be set from the HMI panel and the cutter is entirely made of AISI 304.

- Cooling tunnel - 6 mt

-

Made for food cooling, the hot product is conveyed inside the tunnel where there is a convective forced air flow at a low temperature. The operational parameters can be edited from the operator panel.

- Made of AISI 304

- Polyurethane conveyor belt

- Forced air cooling flow

- Pass-through product height 130/290 mm, belt width 180/250/320 mm

- Cooling lenght 6 m

- Volt 400 Hz 50 – 2,4 kW Threephase 5 poles

-

Made for food cooling, the hot product is conveyed inside the tunnel where there is a convective forced air flow at a low temperature. The operational parameters can be edited from the operator panel.

- Longitudinal cutter

-

Made of a series of circular cutter and a set of distance blocks that can be set according to the needed product lenght.

- System for half longitudinal cut

- System to make half partial longitudinal cut at the moment of the bars production

- System for half longitudinal cut

-

Made of a series of circular cutter and a set of distance blocks that can be set according to the needed product lenght.

- Electric cabinet

- All the electrical components are supplied such as sensors, valves etc. The management is done by central PLC and HMI operator panel. The machine is connected through Ethernet for the remote management as assistance or control of the process.

- Trasversal ultrasound cutter

- It enalbes the machine to work on very sticky products and assure a very clean and precise cut.

- Bar-loading on tray

- It enables to pick the bars from the trasnport to the exit of the cut group,put them on a tray 600x400 mm

HORIZONTAL PACKAGING

| Products | Fruit & cereals snack bars

|

|---|---|

| Dimensions | 33 h x 11 x 105 mm length (Thickness from 5 to 20 mm x 56 x 28 mm / from 5 to 20mm x 28 x 28)

|

| Packaging Usable Film | Polypropilene

|

| Packaging Speed | Max speed 60/70 bpm

|

| Characteristics |

|

| Weights |

Up to 1000g

Up to 5KG MAX

Up to 25KG

|

BACK